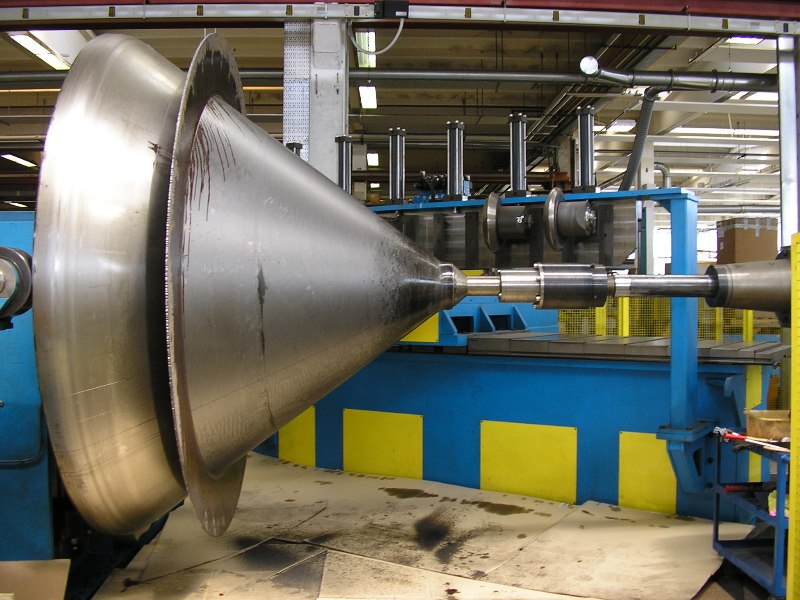

Spinning Lathes

Such machines are able to spin blank steel (ST-37 quality) in plates up to 16 mm. thick and from 10 to 4000 mm. diameter. We also build either hydraulic-sensitive and automatic spinning lathes with Motion Control or CNC, with 1 or 2 slides, ready to work in cold an in hot. Our CNC machines have 2 different levels of programming: the replay machines the worker makes the program manually, recording it. Once it is finished, it can be put in automatic mode. The upper level comes with an external CAD-CAM programming which allows to edit the different strokes and also program all the working parameters: speeds, advances, thickness and accessories very easily and graphically. No specific software knowledge is required.

In both levels, our machines have a special software that allows to copy automatically the profile of the chuck. All our machines are built after a deep analysis of the customer’s needs making possible to incorporate all the features and accessories required for every specific work. We deliver the machines already with the programs of the most important products that our customer manufactures. We also train in our facilities with specific courses, free of charge, the customer staff responsible for the well operation and function of the machine.

After 20 years building CNC machines and analysing all our technical services worldwide, we have developed a CHECK program which allows to connect the machine with our Home computer and detect most of the defaults that might occur. Also possible is to interchange the programs of our customers and assist them with our knowledge and experience.

Flow Forming Lathes(RL, RLE)

The flow forming lathes can work starting from a blank or a pre-form getting from the initial thickness the desired final length. The volume of the material keeps unchanging. We build automatic machines with 2 or 3 working rollers by means of a PLC or CNC, with characteristics according to our customer’s needs. The use of CNC allows getting not only cylindrical or conical, but also other shapes.

These lathes are ready to work laminated materials such as steel, aluminum, copper, brass, stainless, etc. Depending on the characteristics of the piece, this can be obtained by only one stroke, and thickness reduction up to 90%. Machines are able to obtain components from 50 mm. to 1000 mm. and thicknesses from 0.3 up to 30 mm. The usual applications for these machines are kitchenware, army and car industry.

All our machines are built after a deep analysis of the customer’s needs making possible to incorporate all the features and accessories required for every specific work. We deliver the machines already with the programs of the most important products that our customer manufactures. We also train in our facilities with specific courses, free of charge, the customer staff responsible for the well operation and function of the machine.

Trimming and Beading Machines(RB, RBH, RBI)

The trimming and beading machines are used for auxiliary operations after the spinning or press operations. These vertical machines have a bench with a system to rotate the piece and installed with different units to make the different operations. We can build machines to deform up to 10 mm. thickness on steel ST-37 and diameter up to 1800 mm., either cylindrical and polygonal components.

Our technical office, with a wide experience on processes to deform by rotation, can assist you, free of charge, analyzing the most suitable machine or process to make a part you might need.

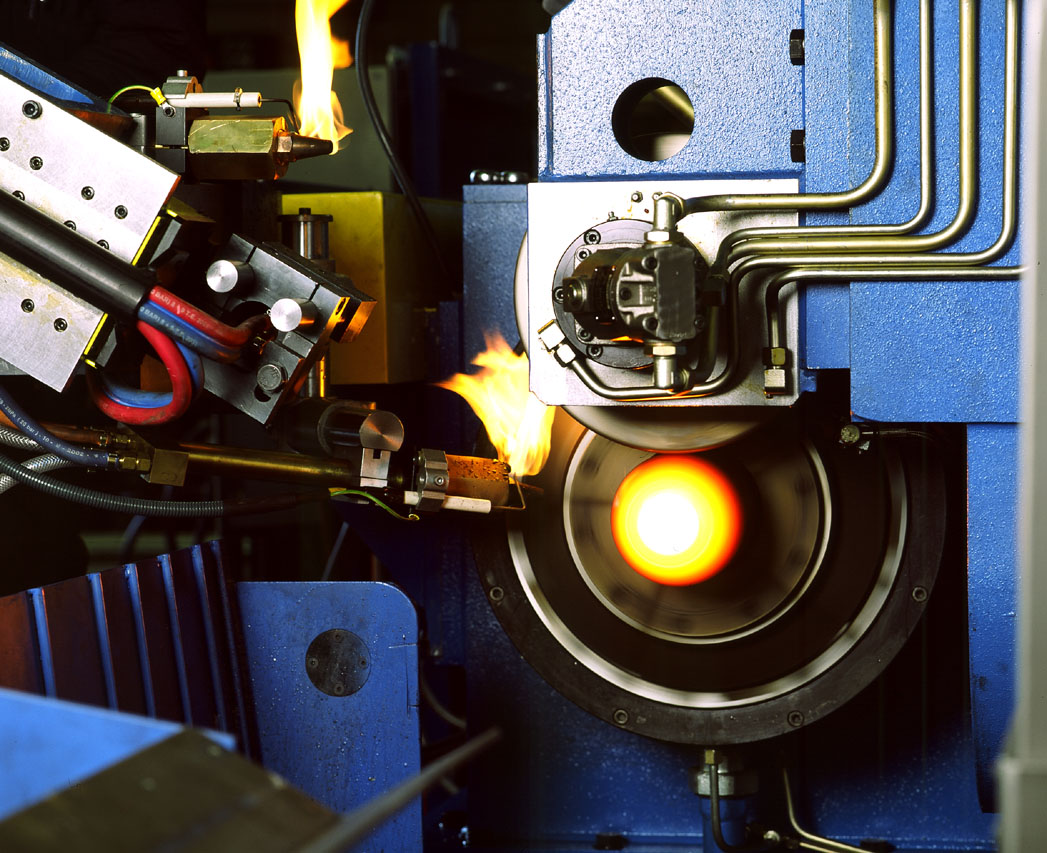

Tube Closing / Necking Machines (CTA, CTS)

These machines deform tubes that have been pre-heated before in order to ease the deformation of the material. They are equipped according to their application and its final use. There are different processes and devices to heat up the tubes: gas, induction … These devices can be installed on the same machine or separately.

These machines can have hydraulic-sensitive, automatic or equipped with CNC, able to work with tubes up to 520 mm. diameter. All our machines are built after a deep analysis of the customer’s needs making possible to incorporate all the features and accessories required for every specific work.

We deliver the machines already with the programs of the most important products that our customer manufactures. We also train in our facilities with specific courses, free of charge, the customer staff responsible for the well operation and function of the machine.

Machinery for the Manufacturing Wheels (MP, MPH)

Machines specially built to manufacture wheels, pulleys in plate, folded, split or poly-V form. Either in vertical action with 1, 2, 3 or more working slides or horizontal action with a turret up to 6 tools and/or rollers.

All our machines are built after a deep analysis of the customer’s needs making possible to incorporate all the features and accessories required for every specific work.

We deliver the machines already with the programs of the most important products that our customer manufactures. We also train in our facilities with specific courses, free of charge, the customer staff responsible for the well operation and function of the machine.

Special Machines

We are specialists to deform blanks and tubes by rotation processes. On this metalworking field, in which we have been working since our foundation in 1885, we build machines specifically designed for every specific application that our customer needs.

All our machines are built after a deep analysis of the customer’s needs making possible to incorporate all the features and accessories required for every specific work.

We deliver the machines already with the programs of the most important products that our customer manufactures. We also train in our facilities with specific courses, free of charge, the customer staff responsible for the well operation and function of the machine.