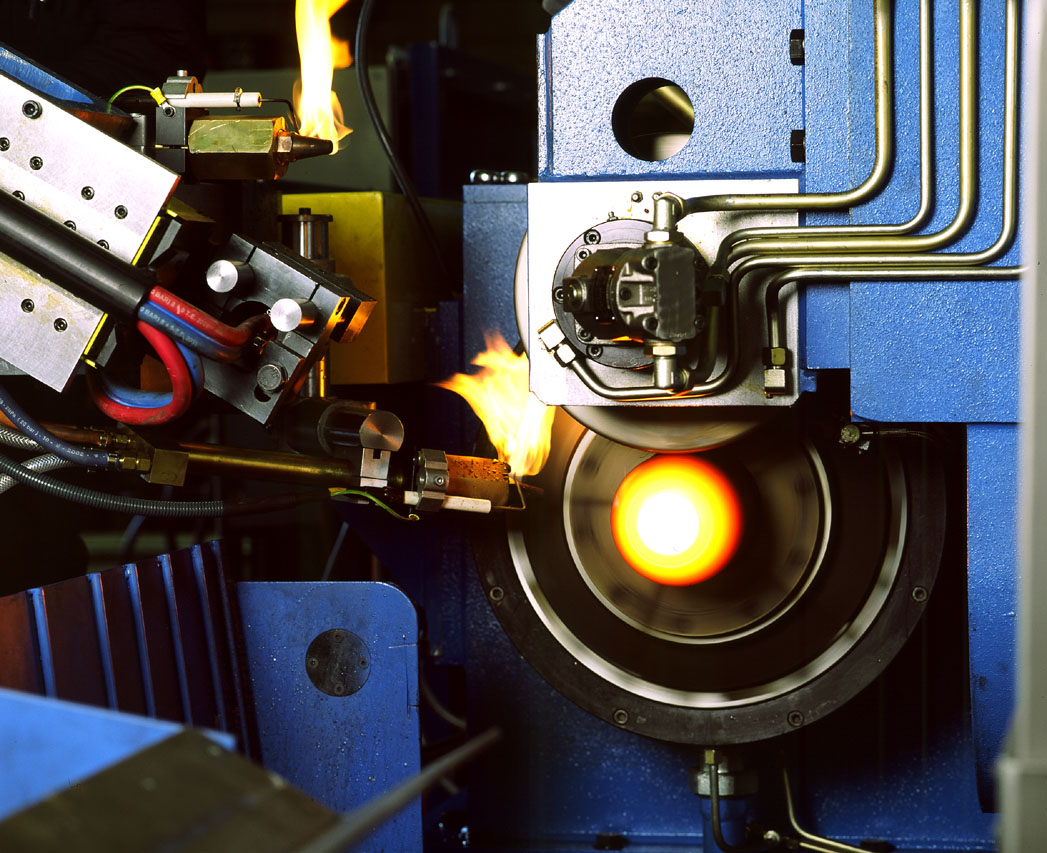

Tube closing machine for CNG cylinders

Necking machine

Necking machine for CNG cylinder or pressure bottle

tube closing and necking machine for CNG cylinder

CNG cylinder tube closing and necking machine

necking and tube closing machine for pressure bottle

Spinning Lathes

Such machines are able to spin blank steel (ST-37 quality) in plates up to 16 mm. thick and from 10 to 4000 mm. diameter. We also build either hydraulic-sensitive and automatic spinning lathes with Motion Control or CNC, with 1 or 2 slides, ready to work in cold an in hot. Our CNC machines have 2 different levels of programming: the replay machines the worker makes the program manually, recording it. Once it is finished, it can be put in automatic mode. The upper level comes with an external CAD-CAM programming which allows to edit the different strokes and also program all the working parameters: speeds, advances, thickness and accessories very easily and graphically. No specific software knowledge is required.

In both levels, our machines have a special software that allows to copy automatically the profile of the chuck. All our machines are built after a deep analysis of the customer’s needs making possible to incorporate all the features and accessories required for every specific work.

We deliver the machines already with the programs of the most important products that our customer manufactures. We also train in our facilities with specific courses, free of charge, the customer staff responsible for the well operation and function of the machine.

After 20 years building CNC machines and analysing all our technical services worldwide, we have developed a CHECK program which allows to connect the machine with our Home computer and detect most of the defaults that might occur. Also possible is to interchange the programs of our customers and assist them with our knowledge and experience.